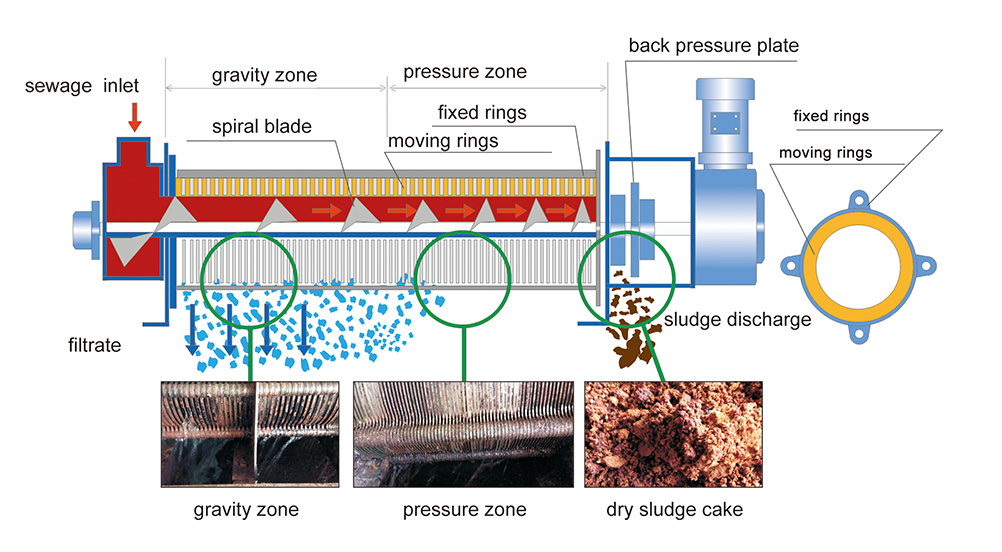

Prinsip Kerja:

Sludge sing dikondisikake dilebokake menyang zona dewatering saka tangki flokulasi. Minangka progresses liwat kesenjangan narrowing kawangun dening batang meneng lan obah rings, meksa di bangun lan banyu mboko sithik squeezed metu.

Banyu kapisah mili liwat longkangan antarane obah lan tetep dering, kang kanthi otomatis di resiki dening gerakan dering piyambak-efektif nyegah clogging lan mesthekake operasi terus. Kue sludge sing dikompres pungkasane dibuwang saka mburi.

Fitur utama:

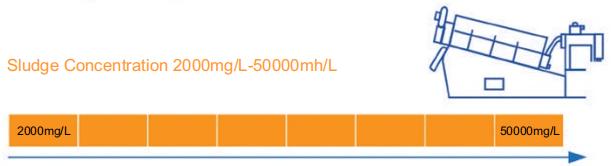

Pre-konsentrasi kanggo endhot konsentrasi rendah

Dilengkapi piring spiral eksklusif, mesin kasebut nindakake pra-konsentrasi sing efisien, saengga cocog kanggo ngobati endapan konsentrasi rendah. Kanthi ngganti dehidrator jinis gravitasi tradisional lan nggabungake proses flokulasi lan konsentrasi, iki nyederhanakake perawatan endapan. Katup kontrol solenoid luwih nambah konsentrasi slurry kanggo kinerja dewatering sing luwih apik.

1. Desain Clog-Free karo Self-Cleaning Rings

HLDS nggunakake obah lan tetep dering tinimbang kain Filter, mbusak masalah clogging lan nyuda kabutuhan pangopènan. Iku utamané cocok kanggo endhot lengo lan kurang konsentrasi, lan ora mbutuhake reresik tekanan dhuwur, minimalake polusi secondary.

2. Low-Speed, Operasi Irit Energi

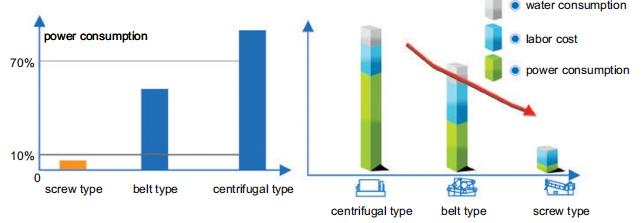

Kanthi kacepetan rotasi sing luwih murah tinimbang sistem sabuk utawa sentrifugal, penet sekrup HLDS nyuda panggunaan energi nganti 87,5% dibandhingake karo sabuk sabuk lan 95% dibandhingake centrifuges. Iku uga mrodhuksi kurang gangguan sak operasi.

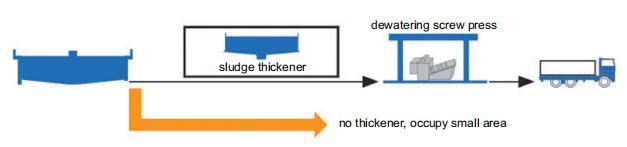

3. Suda Infrastruktur & Biaya Operasi

Mesin dewatering sludge meneng bisa nambani endhot langsung saka aerasi lan sedimentasi tank, mbusak perlu kanggo thickening tank lan ngurangi release fosfor. Mbutuhake ruang lantai sing kurang, nyebabake investasi modal sing luwih murah ing fasilitas perawatan banyu limbah.

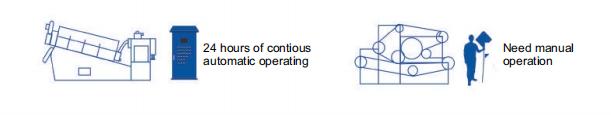

4. Kontrol Otomatis & Operasi Prasaja

Integrasi karo kabinèt kontrol listrik basis PLC, sistem ndhukung operasi kanthi otomatis. Ora ana komponen sing rawan clog njamin kinerja sing stabil lan kurang pangopènan-becik kanggo fasilitas sing mbutuhake operasi tanpa pengawasan 24/7.

Aplikasi:

Pencet sekrup dewatering banget serbaguna lan bisa ditrapake kanggo macem-macem jinis lan industri endhot:

- ✅ Pengolahan air limbah kota

- ✅ Industri petrokimia & kimia

- ✅ Pabrik pulp & kertas

- ✅ Tanduran farmasi lan pewarna

- ✅ Pengolahan daging & susu

- ✅ Limbah tambang

- ✅ Industri percetakan & lukisan

- ✅ Septic tank lumpur

- ✅ Limbah sawit lan peternakan susu

Apa sampeyan ngatur sludge aktif, endhot DAF, endhas campuran, utawa endapan kimia, mesin dewatering screw press iki njamin efisiensi sing unggul lan ngasilake investasi.

Parameter teknis:

| Jinis | Limbah Mentah / Limbah Aktif Sludge / Endapan Kimia | Sludge Udara Terlarut | Sludge Mentah Campuran | ||

| Konsentrasi Sludge (TS) | 0,20% | 1.00% | 2.00% | 5.00% | 3.00% |

| HLDS-131 | ~4kg-DS/jam(~2,0m³/jam) | ~6kg-DS/jam(~0,6m³/jam) | ~10kg-DS/jam(~0,5m³/jam) | ~20kg-DS/jam(~0,4m³/jam) | ~26kg-DS/jam(~0,87m³/jam) |

| HLDS-132 | ~8kg-DS/jam(~4,0m³/jam) | ~12kg-DS/jam(~1,2m³/jam) | ~20kg-DS/jam(~1,0m³/jam) | ~40kg-DS/jam(~0,5m³/jam) | ~52kg-DS/jam(~1,73m³/jam) |

| HLDS-133 | ~12kg-DS/jam(~6,0m³/jam) | ~18kg-DS/jam(~1,8m³/jam) | ~30kg-DS/jam(~1,5m³/jam) | ~60kg-DS/jam(~1,2m³/jam) | ~72kg-DS/jam(~2,61m³/jam) |

| HLDS-201 | ~8kg-DS/j(~4,0m³/jam) | ~12kg-DS/jam(~1,2m³/jam) | ~20kg-DS/jam(~1,0m³/jam) | ~40kg-DS/jam(~0,8m³/jam) | ~52kg-DS/jam(~1,73m³/jam) |

| HLDS-202 | ~16kg-DS/jam(~8,0m³/jam) | ~24kg-DS/jam(~2,4m³/jam) | ~40kg-DS/jam(~2,0m³/jam) | ~80kg-DS/jam(~1,6m³/jam) | ~104kg-DS/jam(~3,47m³/jam) |

| HLDS-203 | ~24kg-DS/jam(~12,0m³/jam) | ~36kg-DS/jam(~3,6m³/jam) | ~60kg-DS/jam(~3,0m³/jam) | ~120kg-DS/jam(~2,4m³/jam) | ~156kg-DS/jam(~5,20m³/jam) |

| HLDS-301 | ~20kg-DS/jam(~10,0m³/jam) | ~30kg-DS/jam(~3,0m³/jam) | ~50kg-DS/jam(~2,5m³/jam) | ~100kg-DS/jam(~2,0m³/jam) | ~130kg-DS/jam(~4,33m³/jam) |

| HLDS-302 | ~40kg-DS/jam(~20,0m³/jam) | ~60kg-DS/jam(~6,0m³/jam) | ~100kg-DS/jam(~5,0m³/jam) | ~200kg-DS/jam(~4,0m³/jam) | ~260kg-DS/jam(~8,67m³/jam) |

| HLDS-303 | ~60kg-DS/jam(~30,0m³/jam) | ~90kg-DS/jam(~9,0m³/jam) | ~150kg-DS/jam(~7,5m³/jam) | ~300kg-DS/jam(~6,0m³/jam) | ~390kg-DS/jam(~13,0m³/jam) |

| HLDS-304 | ~80kg-DS/jam(~40,0m³/jam) | ~120kg-DS/jam(~12,0m³/jam) | ~200kg-DS/jam(~10,0m³/jam) | ~400kg-DS/jam(~8,0m³/jam) | ~520kg-DS/jam(~17,3m³/jam) |

| HLDS-351 | ~40kg-DS/jam(~20,0m³/jam) | ~60kg-DS/jam(~6,0m³/jam) | ~100kg-DS/jam(~5,0m³/jam) | ~200kg-DS/jam(~4,0m³/jam) | ~260kg-DS/jam(~8,67m³/jam) |

| HLDS-352 | ~80kg-DS/jam(~40,0m³/jam) | ~120kg-DS/jam(~12,0m³/jam) | ~200kg-DS/jam(~10,0m³/jam) | ~400kg-DS/jam(~8,0m³/jam) | ~520kg-DS/jam(~17,3m³/jam) |

| HLDS-353 | ~120kg-DS/jam(~60,0m³/jam) | ~180kg-DS/jam(~18,0m³/jam) | ~300kg-DS/jam(~15,0m³/jam) | ~600kg-DS/jam(~12,0m³/jam) | ~780kg-DS/jam(~26,0m³/jam) |

| HLDS-354 | ~160kg-DS/jam(~80,0m³/jam) | ~240kg-DS/jam(~24,0m³/jam) | ~400kg-DS/jam(~20,0m³/jam) | ~800kg-DS/jam(~16,0m³/jam) | ~1040kg-DS/jam(~34,68m³/jam) |

| HLDS-401 | ~70kg-DS/j(~35,0m³/jam) | ~100kg-DS/jam(~10m³/jam) | ~170kg-DS/jam(~8,5m³/jam) | ~340kg-DS/jam(~6,5m³/jam) | ~442kg-DS/jam(~16,0m³/jam) |

| HLDS-402 | ~135kg-DS/j(~67,5m³/jam) | ~200kg-DS/jam(~20,0m³/jam) | ~340kg-DS/jam(~17,0m³/jam) | ~680kg-DS/jam(~13,6m³/jam) | ~884kg-DS/jam(~29,5m³/jam) |

| HLDS-403 | ~200kg-DS/jam(~100m³/jam) | ~300kg-DS/jam(~30,0m³/jam) | ~510kg-DS/jam(~25,5m³/jam) | ~1020kg-DS/jam(~20,4m³/jam) | ~1326kg-DS/jam(~44,2m³/jam) |

| HLDS-404 | ~266kg-DS/jam(~133m³/jam) | ~400kg-DS/jam(~40,0m³/jam) | ~680kg-DS/jam(~34,0m³/jam) | ~1360kg-DS/jam(~27,2m³/jam) | ~1768kg-DS/jam(~58,9m³/jam) |

| Jinis | Dhuwur Discharge | ukuran | Bobot (kg) | Daya (kW) | Banyu ngumbah (L/h) | |||

| L (mm) | W (mm) | H (mm) | kosong | operasi | ||||

| HLDS-131 | 250 | 1860 | 750 | 1080 | 180 | 300 | 0.2 | 24 |

| HLDS-132 | 250 | 1960 | 870 | 1080 | 250 | 425 | 0.3 | 48 |

| HLDS-133 | 250 | 1960 | 920 | 1080 | 330 | 580 | 0.4 | 72 |

| HLDS-201 | 350 | 2510 | 900 | 1300 | 320 | 470 | 1.1 | 32 |

| HLDS-202 | 350 | 2560 | 1050 | 1300 | 470 | 730 | 1.65 | 64 |

| HLDS-203 | 350 | 2610 | 1285 | 1300 | 650 | 1100 | 2.2 | 96 |

| HLDS-301 | 495 | 3330 | 1005 | 1760 | 850 | 1320 | 1.3 | 40 |

| HLDS-302 | 495 | 3530 | 1290 | 1760 | 1300 | 2130 | 2.05 | 80 |

| HLDS-303 | 495 | 3680 | 1620 | 1760 | 1750 | 2880 | 2.8 | 120 |

| HLDS-304 | 495 | 3830 | 2010 | 1760 | 2300 | 3850 | 3.55 | 160 |

| HLDS-351 | 585 | 4005 | 1100 | 2130 | 1100 | 1900 | 1.3 | 72 |

| HLDS-352 | 585 | 4390 | 1650 | 2130 | 1900 | 3200 | 2.05 | 144 |

| HLDS-353 | 585 | 4520 | 1980 | 2130 | 2550 | 4600 | 2.8 | 216 |

| HLDS-354 | 585 | 4750 | 2715 | 2130 | 3200 | 6100 | 3.55 | 288 |

| HLDS-401 | 759 | 4680 | 1110 | 2100 | 1600 | 3400 | 1.65 | 80 |

| HLDS-402 | 759 | 4960 | 1760 | 2100 | 2450 | 5200 | 2.75 | 160 |

| HLDS-403 | 759 | 5010 | 2585 | 2100 | 3350 | 7050 | 3.85 | 240 |

| HLDS-404 | 759 | 5160 | 3160 | 2100 | 4350 | 9660 | 4.95 | 320 |

-

Agen Penghilang Bau kanggo Septic Tank & Sampah...

-

Dewatering Sludge sing Efisien karo Plat Tersembunyi...

-

Agen Bakteri Nitrifikasi kanggo Perawatan Limbah

-

Layar Statis kanggo Banyu Limbah Solid-Cairan Separ...

-

Bakteri Halotolerant - Bioremed Lanjut...

-

Layar Bar Mekanik kanggo Pretreatme Water Limbah...